The HP cone crusher is a com- pressive crusher in which feed material is crushed between a fixed bowl liner and a moveable mantle. Bigger rock particles are crushed

More

HP cone crusher and basic concepts. The HP cone crusher is a compressive crusher in which feed material is crushed between a fixed bowl liner and a moveable mantle. Bigger

More

Nordberg HP Series cone crushers bring together the optimal combination of crusher speed, throw, crushing forces and cavity design. As the name suggests, these proven

More

Cone crushers. Features. Nordberg® HP Series™ cone crushers are reliable rock crushing machines for all demanding quarrying, mining, and tunneling applications. Over the years they have become the most

More

Features. Nordberg® HP100™ cone crusher is designed for high productivity, low operating and wear costs, long service life and high

More

mp series cone crusher technical reference manual... Page 73 Section 2 General Installation Information Foundation ............. . Crusher Clearance Dimensions .

More

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

More

Contribute to lqdid/id development by creating an account on GitHub.

More

Robust crushing performance. Features. Nordberg® HP500™ cone crusher is a versatile rock crushing machine often used in aggregates production, quarrying applications and

More

HP™ (High Performance) Series cone crushers feature a unique combination of crusher speed, throw, and cavity design. This combination has proved revolutionary in providing

More

The Nordberg® HP Series™ cone crusher product family includes altogether nine models. HP100 HP200 HP300 HP400 HP500 HP900 HP3 HP4 HP5 HP6 HP Series cone crushers provide predictable and consistent capacity, end product size, gradation and shape, making them a safe choice for aggregates and mining processes.

More

Nordberg® HP100™ cone crusher is the smallest model of the Nordberg® HP Series™ cone crushers. It is often utilized in aggregates production as secondary, tertiary or quaternary crusher. Characterized by the

More

Less downtime, more confidence. Nordberg® HP500™ cone crusher delivers less downtime and increased operator confidence. Dual-acting hydraulic tramp-release cylinders are used to let the crusher pass tramp iron and to provide a large clearing stroke if needed. The double accumulator combination provides better reactivity of the hydraulic system.

More

Nordberg® HP300™ cone crusher is a medium-sized model in the renown Nordberg® HP Series™ cone crushers family. It is an efficient crusher utilized in aggregates production as well as in mining operations. Depending on the size of a crushing plant. Nordberg® HP300™ cone crusher can normally be found in the second, third or fourth stage ...

More

1. General Nordberg A2020 The crusher controller A2020 is used for controlling GP and HP crushers. The system can be installed on fixed and moving plants. A2020 is a computer system designed for field operation, and it consists of three decentralised components: •... Page 5 Display screen The user interface screen is divided into seven windows.

More

39 Item Part No. Image 1 DE1007 2 DE6000 3 DE6004 4 DE6015 5 DE6006 DE5024 6 DE6007 7 DE0027 tagout)

More

HP™ (High Performance) Series cone crushers feature a unique combination of crusher speed, throw, and cavity design. This combination has proved revolutionary in providing higher capacity and superior product quality, and in

More

(100-125 hp) Maximum feed opening 236 mm (9 19/64”) (C)* GP100 Weight 6.2 t (13,700 lbs) Power 75-90 kW (100-125 hp) Maximum feed opening 135 mm (5 5/16”) (C)* GP300S ... Secondary cone crusher help by enabling smooth flow of even the coarsest feed material by preventing the formation of blockages.

More

Replacement Nordberg HP300 Cone Crusher Parts. SINCO Machinery manufacture an extensive range of aftermarket crusher wear and spare parts to suit the Metso™ Nordberg™ range of HP300 cone crushers. SINCO Machinery have developed an extensive range of manganese to suit the crushing chambers available for each model. Chambers

More

CH830i Cone crusher. Nominal capacity. 61 - 283 mtph (67 - 311 stph) Max. feed size. 211 mm (8 in.) Motor power. 250 kW (335 hp) No of chambers. 5.

More

machine between 130℉ (54℃) and 140℉ (60℃), cooling facilities are to be used. The temperature difference before and after the crusher should be between 1℉ (0.6℃) and. 3℉ (1.7℃) If the temperature difference is

More

HP cone crusher at the lower end of its speed range will increase the cavity volumetric throughput and the product gradation curve can be altered to produce fewer fines. The allowed speed limits can be found in the Nordberg HP cone crusher instruction manual. Before changing the speed of the crusher, consult product support for further information.

More

This page is about SBM cone crusher manual pdf, ... SBM rock crusher cone manual. ... motor main unit SHANGHAI Y225S 4 PDF ... impact crusher handbook, crusher seminar ... parts manual hp 500 crusher - Crusher South Africa. SBM ourcompany cone crusher manual pdf – P(1) –

More

Our innovative Sandvik QH441 mobile cone crusher will provide you with uninterrupted productivity and requires minimal operator intervention. QH441. Features Product data Images ... C13 Acert 328 kW (440 hp)* Transport length 17.2 m (56.5 ft) Transport width 3.0 m (9.8 ft) Transport ...

More

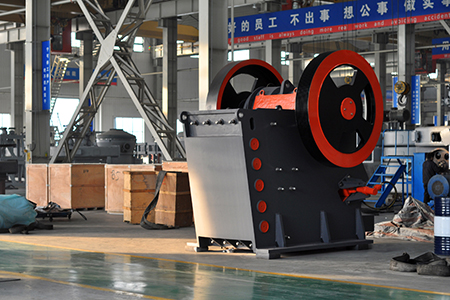

2013年5月30日 HP cone crusher is an ideal crusher for large stone crushing factory and mining industry. Zhengzhou KEFID cone crusher failure-free operation refresh record. ... Failure to follow the safety precautions shown below may result in serious personal shanghai kefid hp cone crusher manual ...

More

Crusher type Cone crusher, hydraulically adjusted Application Minerals processing Crushing stage Secondary, tertiary, quartenary, pebble Max. feed size 300 mm CSS range 10-70 mm Nominal capacity* 179-1,473 mtph Ambient temperature -20°C to +40°C (Contact Sandvik if outside range) Altitude of site ≤ 2000 m (Contact Sandvik if outside range)

More

Maximise your milling efficiency. The FLS mill liners - tailored for the efficiency, durability and safety of your operations. FLSmidth is the full flowsheet technology and service supplier to the global mining and cement industries.

More

Features. Nordberg® HP4™ cone crusher is designed with safety, simplicity and eco-efficiency in mind. It is a robust rock crushing machine used especially in secondary, tertiary, and quaternary crushing stages in aggregates production and mining applications. HP4™ is part of the latest generation of cone crushers with improvements such as ...

More

The Sandvik US373 wheeled cone crusher is engineered to provide your operations with flexibility, sustainability, durability and class-leading productivity. Following the success of the UH373, the new Sandvik US373 offers the same modular design as the UH373, but now also features the highly reliable and powerful Sandvik CS430 cone crusher with a 180

More

HP cone crusher at the lower end of its speed range will increase the cavity volumetric throughput and the product gradation curve can be altered to produce fewer fines. The allowed speed limits can be found in the Nordberg HP cone crusher instruction manual. Before changing the speed of the crusher, consult product support for further information.

More