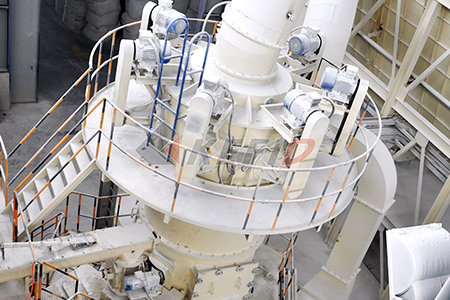

Customer stories Vertical roller mills offer supreme grinding with high energy-efficiency Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit

More

Our best-in-class OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cutting-edge design features consistently deliver the

More

Our range of milling and grinding technologies have been tried and tested around the globe. Our vertical roller mills, horizontal mills, hydraulic roller presses and stirred mills have

More

In 2017, FLSmidth introduced the OK raw mill, which is designed with the same proven technology and modular design as the OK cement mill. FLSmidth’s modular design uses

More

than you need. The ATOX mill will grind and dry coal containing more than 20% moisture in one operation. The possibility of customer-supplied parts, along with the low civil costs that accompany compact mill installation, add to the excellent economy of the ATOX coal mill. Working principles The raw coal enters the mill via a rotary

More

2019年6月9日 OK Raw Mill blev udgivet af rajk-in den 2019-06-09. Læs onlineversionen af OK Raw Mill. Download alle sider 1-8 på AnyFlip. Quick Upload; Explore; Features; Example; ... Vertical Roller Mills (VRMs) have been the standard option for raw Roller assembly and swing lever system

More

2023年9月29日 2. 1. INTRODUCTION The vertical roller mill is the appropriate equipment for grinding and drying of wet materials. Grinding and drying can very efficiently be executed in one machine: Many materials can be ground in vertical roller mills such as: ∗ raw materials ∗ coal ∗ pozzolana / trass ∗ slag ∗ (cement) This paper deals in first place with

More

The OKTM mill can skilfully grind raw or cement feed material and offers parts commonality, simplifying spare parts inventory and facilitating easy switching of parts between vertical roller mills. Our ATOX® coal mill has large rollers with great grinding capability of all types of coal, tolerating moisture levels up to 20 percent. For the ...

More

2016年11月3日 Learn how the FL Smidth Atox® Raw Mill works to grind raw materials for cement production, with this animation video. See how it saves space, energy and delivers reliable performance.

More

2013年5月23日 FLSmidth – OK Vertical Roller Mill Ultimately, re-welding or replacing segments. atox vertical raw mill pdf. FLSmidth – Grinding An extremely compact, atox mill fls in Bangkok, Thailand – Gold Ore Crusher

More

Suppy TOX30 ATOX32.5 ATOX35 ATOX37.5 FLS Raw Coal Vertical Roller Mill Spare Part 12/11/2020. ... Grinding Roller: Atox Raw Mill: Spherical bearing 241/710 ECAK30/W77: 3: Atox Raw Mill: Conical sleeve: 3.106911: 3: Atox Raw Mill: Cylindrical bearing NU 20/800 ECMA: 3: Atox Raw Mill: O-seal dia 1189 x 8 mm: 6:

More

2014年11月2日 ATOX™ raw mill 2 Grinds virtually anything while saving space and energy Key benefits ... Make-FLS 1000 TPH LS Reclaimer Make FLS 700 TPH Raw Mill VRM- FLS ATOX- 52.5 540 TPH. Raw Mill Department. ... Vertical roller mill for raw Application p rocess PDF fileVertical roller mill for raw ...

More

For a coal mill, we usually recommend a light classifying liners and for raw mills we recommend heavy classifying liners. If the raw materials are particularly coarse, a mixed solution might be best. This could be either by replacing the first few rings – e.g., the first 1.5 m of the chamber – with step lining or combining wave lining

More

BALL MILLS Drying Capacity versus Grinding Capacity Example: Mill diameter, Capacity, Max. water in m tph feed mat., % 4.2 100 6.5 5.0 190 4.9 Semi-Airswept Ball Mill (FLS Tirax Unidan) The Effect of a Classifying Lining in a Ball Mill Tirax Unidan Mill with SEPAX Separator Fully Airswept Ball Mill (FLS Tirax) Tirax Mill with SEPAX Separator ...

More

Contribute to lqdid/id development by creating an account on GitHub.

More

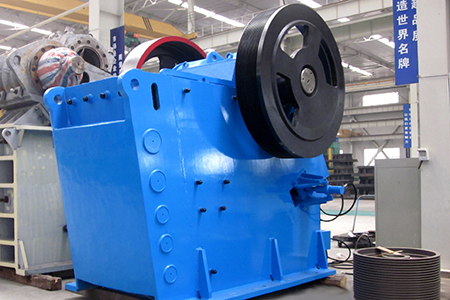

by upgrading your conventional grinding system to FLSmidth’s Hydraulic Roller Press (HRP). Our highly efficient HRP is suitable for both upgrades and new installations. Since 1986, we have installed more than 113 HRP systems in cement plants to grind cement clinker, raw material, and slag. A high level of energy efficiency Long wear

More

Contribute to luoruoping/id development by creating an account on GitHub.

More

Depending the size and application, we can supply both gear stages with slide bearings or roller bearings. The gear casing for the MAAG® GEAR WPU Gearbox is robust welded or cast steel. Additionally, the casing’s even, circular shape guarantees an optimal force flow from the mill table into the foundation of your vertical roller mill.

More

2013年5月6日 Machine Roller Mill Small Scale Wheat Flour Mill Manufacturers Machine Roller Mill Small Scale Wheat Flour Mill cost of raymond roller mills – XSM Grinding Mill Machine Our crusher have very leading status in mine industry (among them: cost of raymond roller mills – In the global have a wide range of markets.

More

Working principle. The ATOX mill uses pressure and shear generated between the rollers and the rotating table to crush and grind raw materials. Feed material is directed onto the grinding table by the feed chute. The rotation of the grinding table accelerates the material towards the grinding track and passes it under the rollers.

More

Our best-in-class OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cutting-edge design features consistently deliver the highest quality products with the greatest efficiency. It is affordable to install and cost effective to operate over your cement plant’s lifetime.

More

OK mill Ball mill OK mill Ball mill OK mill Ball mill 3 days 155 145 225 220 115 110 7 days 255 245 275 260 195 190 28 days 430 420 350 330 425 425 *50/50 clinker and slag mixture Portland cement Slag* RollerTable Table Roller Without hardfacing1 1 65 With hardfacing0.5 3.00.5 2.5 *50/50 clinker and slag mixture

More

Tikaria_Mill Workshop. Metal objects. damage the. roller table. The magnet. removes them. 12. SEPT-07. 29176434 04 Vertical Roller Mills - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or

More

The ATOX mill will From the raw coal silo, the feed is. grind and dry coal containing more extracted and conveyed in enclosed. than 20% moisture in one operation. equipment. Both the mill and separator. 45 - 60 m/s as well as the

More