2017年4月1日 Cerro Verde has a design capacity of 108,000 t/d of hard copper-molybdenum ore (average BWi of 15.3 kWh/t). The circuit is comprised of four 746 kW

More

The HPGR comminution products were evaluated in terms of particle size distribution, specific surface area and average pore volume, and the origin and density of micro-cracks.

More

The Cerro Verde design, borrowed from the designs observed during HPGR benchmarking activities, automatically bypasses metal around the

More

2010年3月10日 Abstract. The successful commissioning of the Cerro Verde project in Peru at the end of 2006 marked the culmination of the efforts of many in the industry over

More

hpgr-faq's The successful commissioning of the Cerro Verde project in Peru at the end of 2006 marked the culmination of the efforts of many in the industry over many years to

More

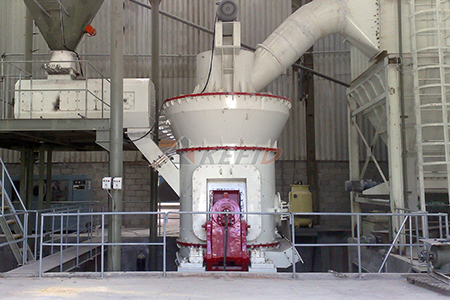

2016年1月1日 Dry comminution technologies, such as High Pressure Grinding Rolls (HPGR) and Vertical Roller Mills (VRM), have been successfully used in other industries such as cement and coal for

More

The 240,000 tpd Cerro Verde Production Unit Expansion concentrator design is based on conventional copper sulfide flotation unit operations, replicating the C1 process but

More

The Cerro Verde Polysius HPGRs have 2 x 2500-kW VSD Twin drives offering an operational speed range of 360–1,200 rpm and a power factor of 0.96. At Ruby Creek

More

En aplicaciones terciarias, los HPGR están obligados a operar en circuito cerrado. Consecuentemente, la alimentación de los molinos no corresponderá a la “descarga” del

More

Es así como después de muchos años de aplicación y consolidación en faenas mineras de la industria del cemento, el hierro y los diamantes, en 2006 comenzó una nueva arremetida en la industria del cobre; de hecho, ya Freeport McMoRan, tiene cuatro modelos 24/17 operando en su mina de cobre y oro Cerro Verde en Perú, y dos modelos 20/15 en

More

2017年4月1日 Furthermore, after commissioning, the HPGR roller wear life was found to average 5000 h with expectations to achieve 6000 h with improved profile design (Hart et al., 2011). Cerro Verde has a design capacity of 108,000 t/d of hard copper-molybdenum ore (average BWi of 15.3 kWh/t).

More

La planta concentradora de SOCIEDAD MINERA CERRO VERDE S.A.A. fue diseñada por la necesidad de procesar sulfuros primarios (Calcopirita y Molibdenita) Informe tecnico del proceso de operaciones de los molinos de rodillo de alta presion (hpgr)

More

2022年3月30日 In neither application was the HPGR principally chosen for its energy efficiency and almost a further 20 years had to pass before the Mining Industry saw the first full scale HPGR-Ball mill installation at Cerro Verde (Vanderbeek et al., 2006), which was chosen due to the 15% energy saving it provided compared to the SAG-Ball mill alternative.

More

2010年5月1日 application was i n Cerro Verde, from Phelps Dodge, Peru (Vanderbeek et al., 2 006). HPGR's are planned to be install ed (already purchased) for the expansion of Freeport Copper, Indonesia ( Mular

More

ABB points out two typical examples of recent HPGR installations with variable-speed drive systems—the Cerro Verde copper mine in Peru and Adanac’s Ruby Creek molybdenum operation in Canada. The Cerro Verde Polysius HPGRs have 2 x 2500-kW VSD Twin drives offering an operational speed range of 360–1,200 rpm and a power factor of 0.96.

More

Actualmente la faena Cerro Verde mueve cerca de 700.000 tpd de material: 360.000 tpd dirigidas a las concentradoras, 40.000 tpd de óxidos para lixiviación y 300.000 tpd de estéril. Esto aumentará a 800.000 tpd en 2018 cuando se amplíen los rajos Cerro Verde y Santa Rosa, y se empiece a minar la zona que los separa uniéndolos en uno solo.

More

At Cerro Verde HPGR tire wear life is projected conservatively as 6,000 hours is equivalent to SAG mill shell liner lives. Based on this, it was felt that HPGR liner wear does not represent a significant technical risk to the implementation of HPGR technology.

More

1.4. UBICACIÓN GEOGRÁFICA DE LA MINERA. Sociedad Minera Cerro Verde S.A.A. (SMCV), opera una mina de cobre al sudeste del Perú, aproximadamente a 25 Km. Del sur de la ciudad de. Propiedad Intelectual de la Universidad Nacional de San Agustín de Arequipa. Arequipa, a una altura de 2700 msnm, esta se ubica exactamente en el.

More

came into operation in Cerro Verde mine in 2006 and have the longest service life by now. Mogalakwena began using one HPGR Polycom-22/16 in 2008, and four HPGR Polycom-24/17 have been operated in Boddington mine since 2009. UDC 622.732 M. KESSLER, E. BURCHARDT (ThyssenKrupp Resource Technology) HIGH PRESSURE GRINDING

More

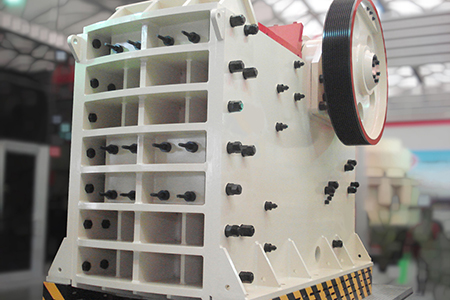

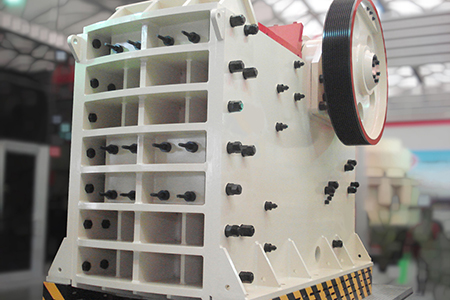

HPGR has come of age, having developed appropriate roll wear abatement technology (Figure 1), and proved itself as an alternative comminution device for ‘hard rock’ applications offering (amongst others) reduced operating cost (energy and wear efficiency). The Cerro Verde (copper/molybdenum), Freeport Indonesia (copper) and

More

2017年4月1日 Furthermore, after commissioning, the HPGR roller wear life was found to average 5000 h with expectations to achieve 6000 h with improved profile design (Hart et al., 2011). Cerro Verde has a design capacity of 108,000 t/d of hard copper-molybdenum ore (average BWi of 15.3 kWh/t).

More

2010年5月1日 application was i n Cerro Verde, from Phelps Dodge, Peru (Vanderbeek et al., 2 006). HPGR's are planned to be install ed (already purchased) for the expansion of Freeport Copper, Indonesia ( Mular

More

Where HPGR technology has replaced traditional methods of crushing and grinding (e.g. SAG or ball mills), it has: Provided excellent throughput capacity and energy efficiency. Decreased energy consumption by up to 40%. Substantially reduced water consumption. Reduced recirculation and wear within crushing and grinding circuits.

More

2016年1月1日 The HPGR and air classification circuit used 20 - 30 % less energy than the HGPR, screen, ball mill circuit. While VRM was estimated to use 10 - 30 % less energy (depending on the type of VRM ...

More

2019年1月17日 habilita los subtitulos (latinoamerica) suscribete https://goo.gl/lmjryw chancado primario en mina cerro verde.explicaciÓn del proceso primario.

More

2 Copper operations Candelaria/Ojos del Salado (80%), Cerro Verde (53.6%) and El Abra (51%) Freeport-McMoRan Operations 7 Copper Reserves 25.9 billion lbs ... Cerro Verde HPGR Installation. 16

More

GRIDING ROLL (HPGR) MODELO 24/ 17-8, USANDO EL LENGUAJE DE PROGRAMACIÓN POLCID EN PLATAFORMA RSLOGIX Y SCADA EN FACTORY TALK VIEW ME PARA EL PROYECTO CVPUE 2 (CERRO VERDE 2)” INFORME DE EXPERIENCIA PROFESIONAL . Presentado por el Bachiller: Reyes Urday, Bryam

More

Cerro Verde’s expanded operations benefit from its large-scale, long-lived reserves and cost efficiencies and have continued to perform well. As a result of several efficiency initiatives implemented over the past several years, Cerro Verde’s two concentrators were able to achieve a combined average milling rate exceeding 400,000 metric tons of ore

More

Cerro Verde is a Peru -based mining company. Its activities include the extraction, exploitation and production of copper from the porphyry copper deposit located southeast of the city of Arequipa. In addition, the company holds a copper sale agreement with Sumitomo Metal Mining, as well as a molybdenum sale contract with Climax Molybdenum Company.

More